Polishing 3-D Printer Fabricated Sleep Apnea Appliances

Recently, an article on increasing retention of a 3-D printer fabricated appliance (Narval CC by RESMED and D-SAD by Panthera) resulted in many requests for information on how to polish these appliances after adjusting them with an acrylic bur. So, here goes, made of type 12 organic polyamide, better known as nylon, these appliances can be easily polished chair-side with the proper tools. Below, I will describe two polishing techniques for these sleep apnea appliances.

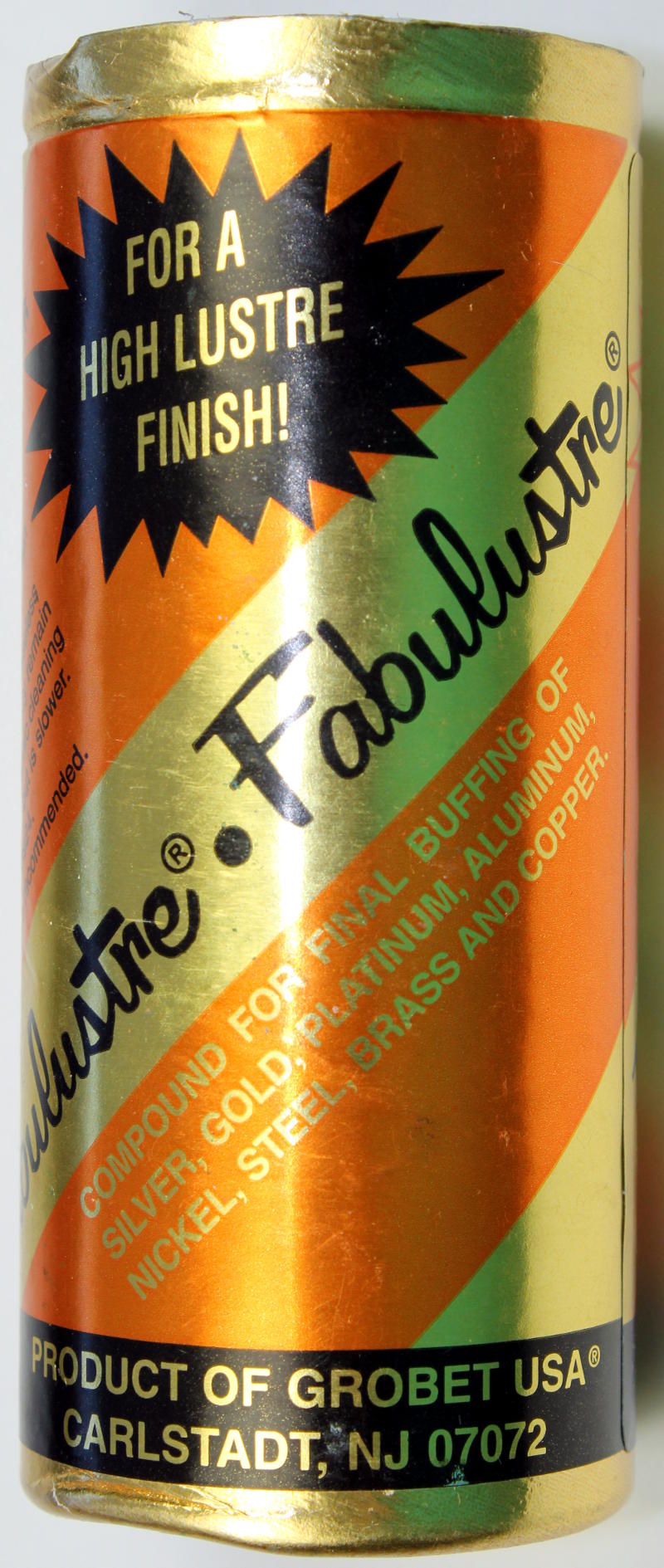

Polishing Technique One: (Fabulustre and Felt Discs)

This technique utilizes a polishing paste named Fabulustre and felt polishing wheels which can be used on a slow speed hand-piece when mounted on a mandrel.

Fabulustre compound helps create a smooth finish. To avoid surface drag-lines do not allow the buffing action to create too much heat. So, a light touch is all it takes. First use a Firm Felt Disc to remove all the imperfections. Then do a final polish with a Soft Felt Disc. Use the Fabultutre paste with both felt discs. This process will remove the burs and fur-like texture left behind after adjusting with an acrylic bur.

Fabulustre Polishing Paste

Firm and Soft Felt Polishing Discs

Polishing Technique Two: (Erkodent Polishing Discs)

This technique is my personal favorite. It utilizes Erkodent Polishing Discs. After adjusting with an acrylic bur, first use the Coarse Erkodent Polishing Disc, which does a wonderful job at removing the burs and tags, and then polish the surface with the Lisko-S Turqoise Polishing Disc. This disc is impregnated with a polishing compound and actually results in a shiny finish. Of course, as with the Fabulustre technique discussed above, ensure you do not generate any heat to avoid drag-lines when using this polishing disc. A light touch is all you need.

Details on Polishing Discs by Erkodent:

Erkodent makes a fine, medium and coarse pre-polishing disc. These discs have an open structure for cooling and work well on soft surfaces. They are well suited for grinding, smoothing and pre-polishing the nylon prior to final finish polish with the Lisko-S Turquoise disc. The maximum recommended hand-piece speed is 4000 Rev/Min, and they are to be used with light pressure.

I have the Coarse Brown disc only and find that often, going directly to the Lisko-S Turquoise disc immediately after the acrylic bur gives me a very nice finish and saves me a step. If you decide to order these coarser discs you may consider ordering an assorted package of 10 (part#223105) which has a sampling of Fine, Medium and Coarse discs for you to establish what works best in your hands.

Erkodent Fine, Medium and Coarse Pre-Polishing Discs

Lisko Polishing Discs FINE White Polishing Disc Part # 223100

Lisko Polishing Discs MEDIUM Grey Polishing Disc Part # 223101

Lisko Polishing Discs COARSE Brown Polishing Disc Part # 223102

Assorted 10 Pac #223105

Lisko-S Turquoise polishing discs have a fine grain, half open stabilized structure that allows removal, rounding off, smoothing and polishing of both soft and hard materials. The ideal hand-piece speed range is 4000 - 10000 Rev/Min. I find that this disc does a great job of cleaning off any tissue tags and burs left behind after an acrylic bur adjustment. Leaving a very nice smooth and shiny finish. Of coarse, it also works great at establishing a final polish after using the Coarser Lisko discs discussed above.

Lisko-S Turquoise Polishing Disc

Erkodent: Lisko-S® Turquoise Polishing Disc Part #223200

Finally, please ensure you are wearing protective eyeglasses whenever you are engaging in these procedures.

John Viviano DDS DABDSM